In 2014, STI Fabrics introduced the industry’s first PFC chemical-free performance fabric.

Sustainable Fabrics Made 100% in the USA

BLEACH- CLEANABLE | NO PFC's | NO FR's | WATER-FREE DYING

Zero PFC Chemicals

Revolution Fabrics does NOT use any PFC Chemicals in our manufacturing process. PFC chemicals are used by other performance fabric brands to achieve a certain level of cleanability. If water beads on a fabric, it has probably been treated with a PFC. These substances, also known as PFOA, PFAS, and PFOS, bond Carbon with Fluorine are not good for your home or the environment.

Up-Cycled Fibers.

We use up-cycled polypropylene to make Revolution Fabrics. In 1963, the Nobel Prize for Chemistry was won by the scientists who discovered a use for this unique fiber.

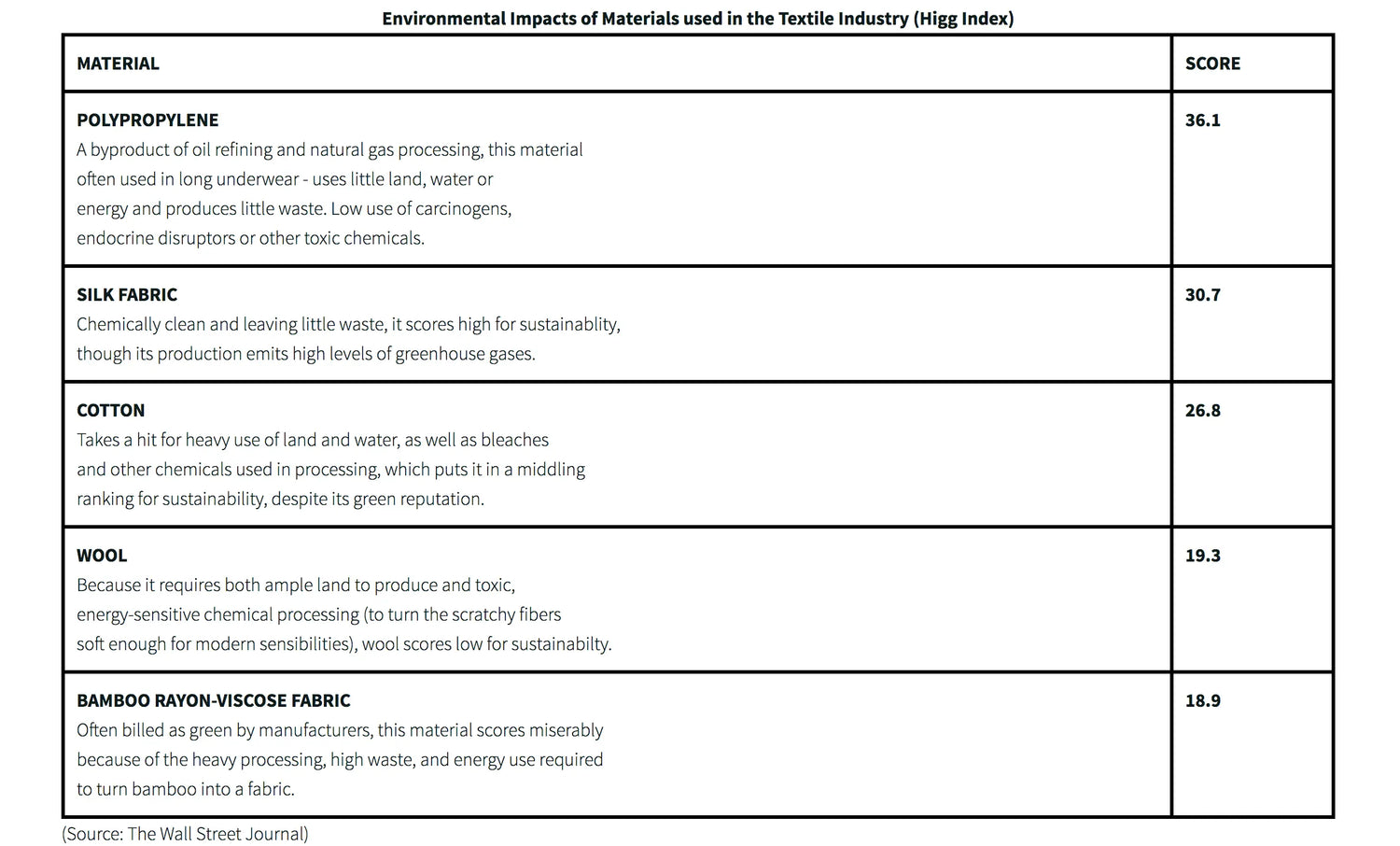

All Revolution Fabrics are made from 100% pre-consumer petroleum byproducts. According to the Higg Index below, because polypropylene is produced from former waste, it has the smallest carbon footprint of any upholstery fiber.

The Higg Index

Polypropylene Scores the Highest

polypropylene scores the highest on the Higg Index with a score of 36.1 due to the fact that it uses little land, water, or energy and produces very little waste. For reference, silk comes in second on the index with a score of 30.7. It scores high for sustainability, but silk production emits high levels of greenhouse gasses.

Cotton comes in third with a score of 26.8. Cotton takes a hit for heavy use of land and water, bleaches, and other chemicals used in processing, which puts it in middling rank despite its green reputation. Wool and Bamboo score even lower due to the fact that they require even more resources and heavier processing due to the scratchy fibers.

Simply put, we use fewer resources.

Historically, the textile industry has used massive amounts of water in the dying process. At STI Fabrics we are committed to using water-free dying techniques. Our dying comes from melting natural pigments into our polypropylene pellets to create the yarn. We then source that yarn within 300 miles of our manufacturing facility.